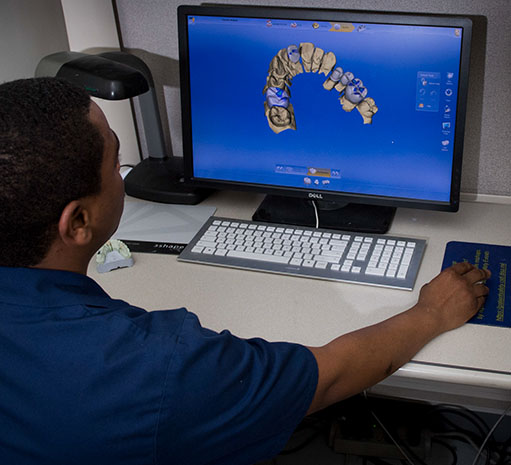

Technological advances are not only changing the dentist-lab relationship, they are also changing how dental labs do business altogether. A decade ago, it was unique for labs to be able to produce restorations using a scanner, computer, and mill. Now, however, it is becoming necessary for their business.

Understanding the latest advances in digital dentistry goes hand in hand with understanding CAD/CAM systems. CAD/CAM (Computer-aided design and computer-aided manufacturing) is a system designed to improve manufacturing and creation of dental restorations, like dental prostheses, including crowns, crown lays, etc. But how would CAD/CAM help your lab?

CAD/CAM software offers a wide range of digital options to improve workflow while saving time and money. Indeed, these advances will change the usual workflow between lab and clinicians as well. The digital solution will open the doors to faster turnarounds coupled with reliable quality. Which, in turn, helps labs compete in a tough market. Designers can use the software to create restorations quickly, as well as use the tools to tailor the restorations to their style. Digital solutions will also allow labs to broaden their product offering by including restorations such as surgical guides and fixed hybrid dentures.

There are many software products within the CAD/CAM system which we believe will help labs in their daily operations.

This system brings together 3D Scanning, CAD modeling and the widest range of indications, restorative component libraries, and third-party device integrations. The 3Shape Dental system allows labs to design everything from a new smile to a complex implant surgical design with the final restorations – all in one process.

This software is designed to integrate into the architecture of the Ceramill system. Indeed, the Ceramill Mind design software considerably simplifies the framework fabrication process and covers a comprehensive range of indications from crowns, bridges, inlays/onlays and telescope crowns to customized abutments. Most importantly, it does so with complete and seamless integration for optimum results:

-

Reduces costs and improves efficiency

-

Improves transparency to lab work status

-

Flexibility to accommodate new requirements

-

Improves quality and compliance

The Dental Wings Open System, commonly named DWOS, is a platform that drives 3D scanners. The DWOS cover a complete range of dental indications such as crowns, implant bars and bridges, full and partial dentures, custom abutments, onlays, veneers and more. Furthermore, DWOS allows labs to collaborate in real-time with their implant-placing and restoring dentist customers through DWOS Cooperation to design and manufacture custom healing abutments, provisional and surgical drill guides.

Unique CAM is designed exclusively for dental applications. It is an effective, user-friendly CAM software for four-and-five-axis milling machines. It was specifically developed to mill simple crowns, bridges, abutments/telescopes, and implant bridges. Its best feature allows to produce extremely smooth surfaces, increase productivity, and reduce hand-finishing as well as calculation time.

This software enables computer-aided, automatic connection of several single restorations. This improves the safety and quality of the entire pressing process and shortens the spruing procedure significantly. The process can be completed on a 3D printer, which is transferred to the pressing process for outstanding benefits for the labs:

-

Time effective and increase of processing safety during spuing

-

Exact definition of color graduation

-

Manual adjustment of sprues is possible

-

Easy attachment to the investment ring base

This software provides freedom of design and materials for creating restorations, removable partial frameworks or screw-retained bridges and bars. With its CAD components, the software is independent of the scanning and production unit and is open for flexible STL integration in existing scanners and machines. Additionally, the inLab Software does not require updates, there’s no expiry date, no annual license fee, and no pay-per-unit fee.

What does the future hold?

CAD/CAM will continue to evolve and be indispensable in the dental industry for one simple reason: CAD/CAM systems manufacture products that allow a smoother, more predictable outcome. Lab business will get more competitive over the years with similar CAD/CAM systems and materials and will need to change the way they serve their customers. With that said, labs will need to move from a production-base lab to a service lab, by sharing knowledge for treatments and adding more services for the dentists, for example.

Digital is the future. It’s not just the future of dentistry – it’s the future of all industries today. Labs need to seize this opportunity and make the most of it.