The goal when creating zirconia restorations, such as monolithic zirconia, is to make them both functional and natural-looking. Sturdy, lifelike restorations, especially those made of monolithic zirconia, will achieve the best patient satisfaction. So, if you can supply those ideal restorations, dentists will flock to your lab.

Unfortunately, in many cases, “functional” and “natural-looking” often come at each other’s expense.

Realistic, natural-looking finishes are achieved with the layering method. But layered restorations aren’t as durable as their monolithic counterparts. You don’t have to dwell on this notion, though.

There’s a way for monolithic zirconia designs to achieve the same natural aesthetic as layered zirconia cases. You’ll be providing dentists with sturdy, realistic cases with this kind of innovation. This guide will show you how to do it:

Use a Natural-Looking Base Material

Monolithic designs consist of a single material. That means these cases don’t have a separate outer material to give a supposed translucent look, unlike layered restorations that consist of a substructure plus filler layers.

For monolithic designs to achieve a layered look, the material — which acts as structure, filler, and finish — must already have the desired appearance from the get-go.

Zirconia has developed over the years to become more translucent and lifelike without compromising flexural strength. This allows for a more realistic zirconia restoration.

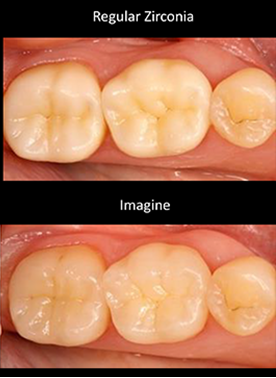

Source: Jensen Dental

Shown in the upper image is a molar case made with the typical, opaque zirconia. Below it, you’ll see the same exact model made with Jensen Dental’s Imagine High-Translucency Zirconia. Notice how the high-translucency zirconia has more of the reflective and translucent properties of a tooth. This results in a more natural-looking monolithic case.

Here are some types of zirconia you’d want to take note of for realistic zirconia restorations:

- High-translucent zirconia: This type of zirconia is highly translucent with a more natural appearance than traditional zirconia.

- Ultra-translucent zirconia: Ultra-translucent zirconia is a newer type of zirconia that is more translucent than high-translucent zirconia.

- Zirconia-reinforced lithium silicate: This one’s more lithium silicate than it is zirconia. This hybrid material combines the translucency of lithium disilicate with the strength of zirconia. It achieves this by infusing zirconia particles in a lithium silicate matrix, combining the properties of the two ceramics.

These materials can be milled, pressed, or 3D printed. Once the case shape is made, the monolithic zirconia goes into a furnace for sintering.

It’s important to note that monolithic zirconia restorations only need to be fired once. Since the entire case is made of only one material – zirconia, there’s no need to account for multiple coefficients of expansion (COE). So, you’ll be saving time and money with the sintering process.

Once the monolithic zirconia restoration is made and sintered, you can use liquid ceramic to finish it. Liquid ceramic is more effective for monolithic cases, as opposed to the traditional stain and glaze.

Use a Liquid Ceramic for Finishing

If the dentist is happy with the color of the sintered zirconia case, you can simply polish it. But usually, dentists will need particular shades and characterizations to blend with the patient’s surrounding teeth. That’s where liquid ceramic comes in.

Liquid ceramic comes in various translucencies and shades. Dental technicians can create realistic zirconia restorations, complete with visual depth and nuance, using liquid ceramics. A monolithic design finished with liquid ceramic has the same aesthetic properties as a layered restoration. A diamond inspector won’t be able to tell the difference.

Notice how the monochromatic case on the left is transformed into a more characterized restoration, as shown on the right. It features a crack line and some hypocalcification, making it look all the more natural.

Source: Jensen Dental

In addition to this realism, the amount of space liquid ceramic requires is incredibly small. Applied liquid ceramics consume 0.1mm to 0.2mm of case space, whereas typical layering ceramics used in layered restorations need about 1.5mm of space.

Adding even a millimeter of layering – though it will make a case more realistic – will make it bigger than it should be. Liquid ceramic can achieve that lifelike look without significantly increasing the case’s overall size.

MiYO Esthetic System

One notable liquid ceramic you can use is MiYO Esthetic. MiYO, uses formulated liquid ceramics to achieve realistic dental restorations. It’s also compatible with all zirconia and lithium disilicate materials, allowing it to be easily integrated into any lab’s workflow.

Another key feature of the MiYO Esthetic System is its ability to withstand color shifts during the firing process. So how a case looks as you’re finishing it is exactly how it will come out of the furnace.

As a result, MiYO eliminates a tremendous learning curve for dental technicians.

What Lifelike Monolithic Zirconia Restorations can do for Your Lab:

Don Cornell and Nina Rapuano of Jensen Dental have an entire webinar that discuss how their company has reimagined the monolithic restoration process. As a result of their innovation, the dental labs they service can now create lifelike monolithic zirconia restorations, saving them time and money while increasing output.

Here are some of the benefits they’ve discussed in the webinar:

Optimized Learning Curve

As mentioned earlier, there’s a steep learning curve when it comes to making dental restorations, particularly layered ones. This curve can bottleneck your dental lab’s efficiency.

Some reasons for this learning curve include color shifting during sintering and the various coefficients of expansion that dental techs work with.

Normally, the colors of glazes and stains shift during the sintering process. In order to achieve the desired color and finish, dental technicians must account for the color shift during sintering. So, as they’re staining and glazing, what they see in their hands won’t necessarily be what the final, sintered case would look like. This can create errors during sintering, prompting the dental lab to start over.

Apart from the post-sintering color, the different COEs of the structure and filler materials also require a close eye. If the different materials in a layered restoration have incompatible COEs, it can damage the case and cause patient discomfort.

So, working with layered restorations can be a really technical, specialized task.

However, using a liquid ceramic, like MiYO, on a monolithic case is — as Don Cornell puts it — as easy as painting. He further elaborates on MiYO’s ease of use, saying “the only limiting factor is do you understand what teeth look like?”

Don also jokes that you can paint a duck on a restoration if you so wish. Then, once it’s fired, the case will come out with the duck.

This means that novices can be brought into the lab and, within a day or two, will start confidently “painting” teeth; complete with depth, contour, and natural imperfection.

Added Value for Dentists

In addition to the optimized learning curve, monolithic restorations can have a tremendous added value — especially if they look more natural than traditional monolithic cases.

Since monolithic restorations require less time, material, and labor, they are less expensive to make than layered restorations. But that doesn’t mean you’ll have to charge less for a realistic monolithic case.

While the cost for a customer on a layered restoration and a monolithic case may be the same, the added durability of a monolithic case has the potential to justify an additional charge.

At the end of the day, dentists aren’t paying for how “quick and easy” something is to make; they’re paying for the value you bring to them. This added value is good for your dental lab’s margins and will improve your client satisfaction.

Quicker, More Efficient Production

Lifelike monolithic zirconia restorations aren’t just sturdier and more appealing. They’re quicker (and easier) to make, too.

With a monolithic approach, you can achieve a faster workflow for your dental technicians. You’ll increase your case production and achieve timely delivery for your dentists.

There are loads of optimizations in the case-creation process when you use monolithic restorations.

- Shaping a monolithic case is much quicker than layering a restoration.

- A monolithic case is made from a single material. So, it only needs to be sintered once before finishing.

- MiYO Esthetic liquid ceramics can be applied on top of each other without sintering between coats and layers.

- The finishing process is less likely to have errors since the case will look the same during the “painting” process and after the case is fired.

Don estimates that labs can double their output with their reimagined monolithic restoration process. This means that you’ll create twice as many cases for the same manpower and labor cost.

Making Realistic Monolithic Restorations Easy

As dental restoration technology becomes more advanced, the barrier between form and function will shrink further and further. Once you can create monolithic zirconia restorations that look like layered cases, your dental lab’s workflow, efficiency, and delivery will improve. In addition, dentist satisfaction will increase, and you’ll see more return clients.

To speed up your operations even further, you can enlist the help of a digital design service like Evident. The only limiting factor after you’ve optimized the restoration-creation process is how many 3D designs you can produce prior to 3D printing and milling.

With Evident’s comprehensive solutions and world-class support, you can elevate your dental business and overcome workflow bottlenecks. Don’t miss out on the opportunity to transform your lab with Evident’s cutting-edge technology and expertise.