Digital dentures are in high demand. This guide will help you transition to digital denture production or refine your current Exocad workflow.

Why Transition to Digital Dentures?

Cost Efficiency

- Digital dentures significantly reduce costs associated with materials, labor, and dentist time.

- The turnaround time is faster compared to conventional dentures.

Enhanced Efficiency

- The digital process eliminates numerous manual steps involved in conventional denture production.

- Digital workflows streamline processes from intra-oral scans to pre-set bite registrations, ensuring higher accuracy and fewer appointments.

Cleaner and More Accurate

- The digital approach is much cleaner, avoiding the messy manual processes.

- Early bite registration increases accuracy, reducing the need for multiple try-ins.

Options for Digital Dentures

Milled vs. Printed Dentures

- Milled Dentures: Offer superior longevity and strength but are more expensive and time-consuming to produce.

- Printed Dentures: Cost-effective and faster to produce, though they may not last as long as milled dentures.

Hybrid Approaches

- Monoblock Dentures: Made from a single material, offering immediate try-in and increased strength.

- Combination of Techniques: Use of milled or printed bases with carded teeth provides flexibility based on dentist preferences.

Advantages of Printing Dentures

- Cost-Effective: Resin for printing is cheaper compared to milling materials.

- Speed: Printing multiple denture bases simultaneously saves significant time.

- Quiet Operation: Modern printers are quiet, making them suitable for various office environments.

- Remake Convenience: Digital designs allow for easy remakes at the click of a button, enhancing patient satisfaction.

Drawbacks of Printing Dentures

- Longevity: Printed dentures may not last as long as milled ones, but they are sufficient closer to permanent as the resin material improves

- Strength: Proper processing is crucial to ensure the strength of printed dentures.

- Processing Complexity: Requires meticulous adherence to manufacturing specifications to avoid weakening the dentures.

Milling Dentures: Pros and Cons

- Durability: Milled dentures are highly durable and last longer.

- Time-Consuming: Milling is slower and more expensive compared to printing.

- Quiet but Requires Space: Milling machines need a designated space due to noise and operational requirements.

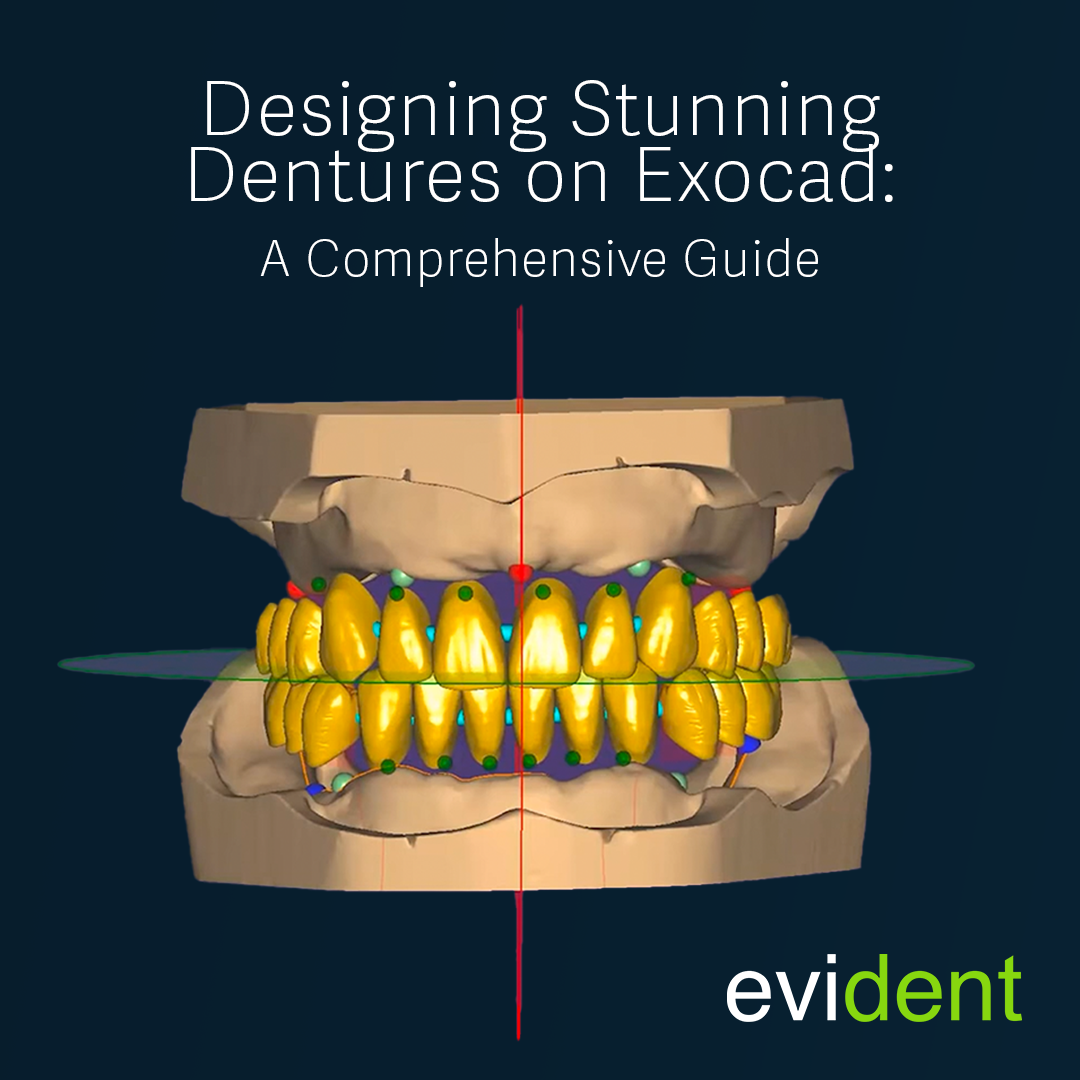

Designing Digital Dentures with Exocad

Getting Started

- Basic Model Analysis: Mark key areas such as the incisal papilla, tuberosities, and retromolar pads for accurate occlusal plane alignment.

- Teeth Setup: Choose from various teeth libraries, with options for scalable teeth for customization.

Advanced Features

- Manipulation of Teeth: Exocad allows for free-forming, scaling, and repositioning of teeth for optimal results.

- Library Downloads: Access a wide range of teeth libraries for diverse design options.

- Undercut Management: Adjust insertion directions and undercuts to ensure a perfect fit.

Material Choices

- Lucitone Resin: Highly recommended for its bonding strength and protection against pitting.

- Customizable Options: Flexibility in using different materials and combining techniques to meet specific needs.

Future of Digital Dentures

The field of digital dentures is rapidly evolving, with advancements in materials and technology enhancing durability and aesthetics. The future promises stronger and more translucent materials, further bridging the gap between digital and conventional dentures.

Conclusions

Embracing digital dentures with Exocad not only streamlines your workflow but also improves the quality and efficiency of denture production. Whether you choose to print, mill, or combine both techniques, the benefits of going digital are undeniable.

Got questions or insights? Feel free to share in the comments below, and let’s continue the conversation on the exciting future of digital dentures.